Configuration Strategies for What a Gear Motor Is in Agricultural Machinery Equipment Upgrades

The agricultural sector is undergoing a rapid transformation, driven by the increasing need for efficiency, precision, and sustainability. Technological advancements are no longer a luxury but a necessity for farmers aiming to maximize yields, minimize resource consumption, and navigate the challenges of climate change. At the heart of this evolution lies the upgrade of existing machinery, often focusing on powertrain components like gear motors. Understanding the nuances of gear motor configuration is crucial for optimizing agricultural equipment performance and achieving these critical goals. This article delves into the role of gear motors in modern agricultural machinery, explores key configuration strategies, and highlights the potential of these components in driving sustainable farming practices. We will also touch upon how recent advancements like AI-powered predictive maintenance are changing the landscape.

The Vital Role of Gear Motors in Agricultural Machinery

Gear motors are integral components in a wide range of agricultural machinery, providing the necessary torque multiplication and speed reduction required for various operations. Unlike direct-drive systems, gear motors allow engines to operate at optimal speeds while delivering the power needed to drive implements like sprayers, harvesters, seeders, and irrigation pumps.

The benefits are numerous:

- Torque Multiplication: Gear motors significantly increase torque output, enabling machinery to overcome resistance and perform heavy-duty tasks.

- Speed Reduction: They reduce motor speed to match the requirements of the driven equipment, optimizing performance and efficiency.

- Compact Size and Lightweight Design: Modern gear motors are designed for space-constrained agricultural applications, contributing to equipment optimization.

- Reliability and Durability: Built to withstand harsh environmental conditions, gear motors offer long-term reliability and minimize downtime.

- Energy Efficiency: Advancements in gear motor design have led to improved energy efficiency, reducing fuel consumption and operational costs.

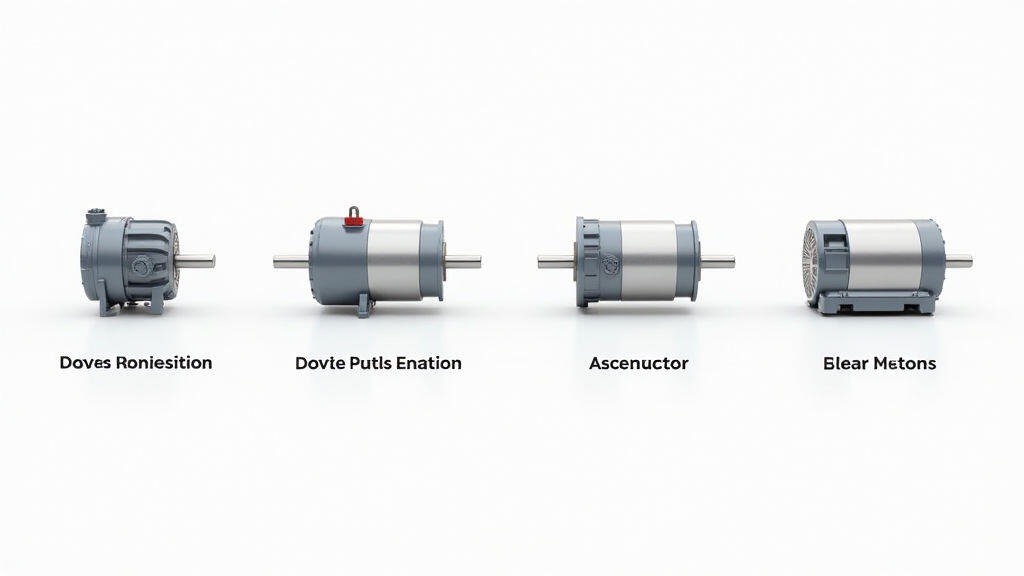

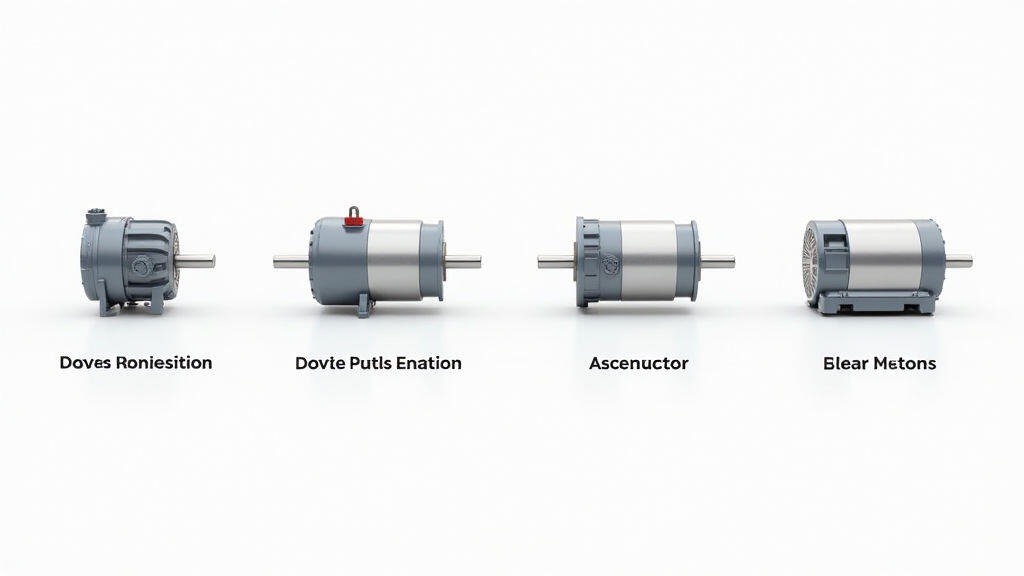

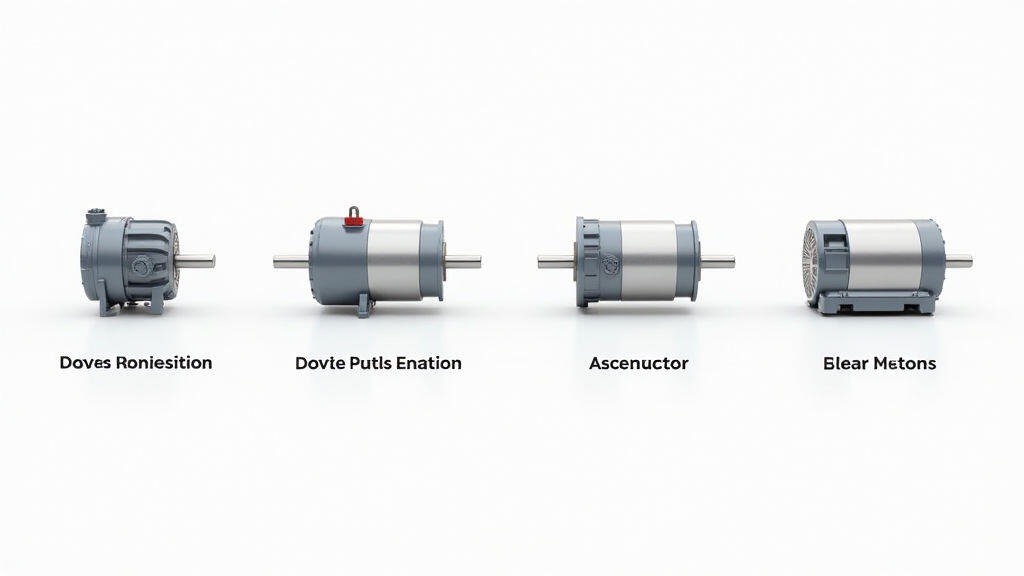

Understanding Gear Motor Types and Their Applications

Several types of gear motors are commonly employed in agricultural machinery, each tailored to specific needs:

- Spur Gear Motors: Simple and cost-effective, suitable for applications requiring moderate torque and speed. Often found in smaller implements like cultivators and tillers.

- Helical Gear Motors: Offer smoother and quieter operation compared to spur gears, making them ideal for applications where noise reduction is a priority. Used in irrigation pumps and some harvesting equipment.

- Bevel Gear Motors: Provide a compact design and are well-suited for applications with angular power transmission, such as steering systems in tractors.

- Worm Gear Motors: Offer a high gear ratio and self-locking capabilities, making them suitable for applications requiring precise positioning and holding torque, like robotic harvesting arms or automated seeders.

- Planetary Gear Motors: These are efficient, compact and durable, well-suited for complex applications, often found in precision agriculture systems.

The selection of the right gear motor type is paramount and depends on factors like required torque, speed range, space constraints, and operating environment.

Optimizing gear motor performance involves more than just selecting the right type. Several configuration strategies can further enhance efficiency and reliability:

- Gear Ratio Selection: Choosing the optimal gear ratio is fundamental. Too low a ratio results in insufficient torque, while too high a ratio wastes energy. Detailed load analysis and performance modeling are essential for accurate selection.

- Motor Power Matching: The gear motor's motor power should be matched to the load requirements of the driven equipment. Undersized motors lead to stress and failure, while oversized motors are inefficient.

- Lubrication System: Proper lubrication is critical for gear motor longevity. Selecting the appropriate lubricant viscosity and implementing a regular lubrication schedule prevents wear and tear. Modern systems are leveraging smart lubrication, monitoring lubricant condition and issuing alerts for replacement.

- Cooling System: Gear motors can generate significant heat during operation. Implementing adequate cooling, whether through forced air or liquid cooling, prevents overheating and ensures optimal performance.

- Vibration Damping: Implementing vibration dampeners reduces noise and extends the lifespan of the gear motor, especially crucial in environments with rough terrain.

- Advanced Control Systems: Integrating gear motors with advanced control systems allows for precise speed and torque control, adapting to changing operating conditions and optimizing performance. This is crucial for applications like autonomous tractors and precision irrigation.

The Rise of Predictive Maintenance and AI Integration

The agricultural industry is increasingly embracing Industry 4.0 principles, including predictive maintenance. AI-powered systems are being deployed to monitor gear motor performance in real-time, analyzing data from sensors to detect anomalies and predict potential failures. This allows for proactive maintenance, minimizing downtime and extending component lifespan.

For example, MES-Drive is actively incorporating AI algorithms into its gear motor designs and monitoring systems. These algorithms analyze data such as vibration, temperature, and electrical current to identify potential issues before they escalate. This predictive capability allows farmers to schedule maintenance during planned downtime, avoiding costly disruptions to operations. MES-Drive’s system can also optimize gear ratio and lubrication parameters based on real-time usage data, further enhancing efficiency and extending the life of the gear motor.

Sustainable Farming and the Future of Gear Motors

The drive towards sustainable farming practices is fueling innovation in the agricultural machinery sector. Gear motors are playing a vital role in this transformation by enabling:

- Precision Agriculture: Gear motors facilitate the operation of precision agriculture technologies like variable rate application systems and robotic harvesting, enabling targeted resource use and minimizing waste.

- Reduced Fuel Consumption: Energy-efficient gear motor designs contribute to reduced fuel consumption, lowering emissions and improving the environmental footprint of farming operations.

- Autonomous Machinery: Gear motor advancements are essential for the development of autonomous tractors, harvesters, and other agricultural robots, enabling optimized operations and resource utilization.

- Electrification: As the industry moves towards electrification, gear motors will be crucial in driving electric tractors, harvesters, and other power-intensive agricultural equipment.

Conclusion

Gear motors are indispensable components in modern agricultural machinery, enabling efficiency, precision, and sustainability. Proper configuration, encompassing gear ratio selection, motor power matching, lubrication, cooling, and advanced control systems, is crucial for maximizing performance and minimizing downtime. The integration of AI-powered predictive maintenance, as demonstrated by companies like MES-Drive, is further enhancing gear motor reliability and extending component lifespan. As the agricultural sector continues to evolve, the demand for high-performance, energy-efficient, and reliable gear motors will only increase. These advancements are not just about improving current machinery; they are about paving the way for a more sustainable and technologically advanced future for farming. The convergence of gear motor technology with AI and automation presents a powerful opportunity to reshape agricultural practices and address the challenges of feeding a growing global population while minimizing environmental impact.

Leave A Reply

Your email address will not be published. Required fiels are marked